Flox Oxygen Sensor

The WPI FLOX oxygen sensor is ideal when samples need to be left unchanged for long periods of time.

- Overview

- Specifications

- Links

Detect O2 for real-time analysis.

Key Features

- Optical sensors with fluorescence-sensing detectors as an effective replacement for conventional chemical sensing devices

- Fluorescence lifespan, phase, and intensity measurements

- This device is cost-effective because to LED-based photometry; it costs about half as much as similar phase measurement systems

- Outstanding stability, incredibly little drift, and minimal phase noise

- Easy calibration, configuration, and control

- Oxygen Monitoring Kit with:

- Phase measurement system

- Temperature probe

- Select sensor patches when ordering

Options

FLOX-PATCH - Non-Invasive Oxygen Monitoring Kit including a phase measurement device and a temperature probe; when ordering, choose sensor patches

FLOX-PROBE - In situ oxygen monitoring kit with temperature probe and phase measurement system; choose sensor when ordering

Benefits

- Self-contained benchtop system that is resistant to stray light and fiber bending

- The unit's simplicity of setup and control, stability, and sensitivity make it ideal for long-term studies.

- You have various alternatives thanks to three coatings for probes and patches.

Applications

- Applications for oxygen sensing that need stability and sensitivity to drift that must be left alone for extended periods of time

- Check the O2 partial pressure in aqueous solutions, vapors, and gases as well as in non-aqueous vapors and solutions

- Check for oxygen traces in gases and liquids

The FLOX instrument measures the lifetime, phase, and intensity of fluorescence. For simple experimental setup and control, it uses filter-based wavelength selection along with LED excitation and photodiode detection.

Self Contained Unit

Due to its small size and self-contained design, it is resistant to fiber bending and stray light. Also, it features low optical and electrical crosstalk, a large dynamic range of optical intensity, low drift and phase noise, and other positive characteristics.

FLOX is particularly helpful in oxygen sensing applications where stability and sensitivity to drift are critical and sample setups must be left in place for extended periods of time.

Excellent for Long Term Study, Simple Setup

The new oxygen detecting system uses filter-based wavelength selection along with LED excitation and photodiode detection to evaluate fluorescence lifespan, phase, and intensity. The system is easy to configure and use. This device is perfect when stability and sensitivity to drift are crucial for your oxygen sensor experiment. It is ideal for uses when sample setups need to be left alone for extended periods of time.

For Patches and Probes, There are Three Coating Options

The transducer materials, which are put to the tips of optical fibers or to substrates like patches or cuvettes, are what make up optical sensors since they alter their optical properties in response to particular analytes in their immediate surroundings.

OXY — A fiber optic fluorescence probe with a specially coated oxygen sensing tip serves as the industry-standard oxygen sensor for measuring the partial pressure of oxygen in gases and aqueous solutions.

HIOXY is made to measure the partial pressure of oxygen in non-aqueous vapors and solutions. Oils, alcohols, and vapors and liquids made of hydrocarbons are all compatible with the sensor coating chemistry.

Monitoring oxygen traces in gases and liquids can be done using FOSPOR, a new kind of very sensitive sensor coating.

The low-power, highly sensitive, reversible, and stable oxygen sensor probes are perfect for remote monitoring. The probe tips' thin layer prevents oxygen from being consumed, enabling constant contact with the sample. They are perfect for viscous samples and unaffected by changes in pH, ionic strength, salinity, or biofouling.

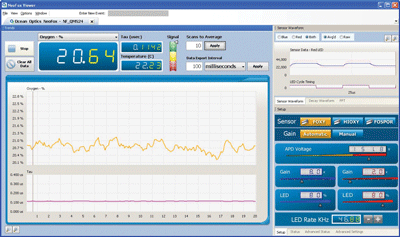

Oxygen readings are displayed on a linked PC by FLOX software.

You can also visit site of the manufacturer.

AL300 - A 500 µm OD (300 µm core diameter) aluminum-jacketed optical fiber probe for applications that require fine spatial resolution. 300 µm alµminµm-jacketed fiber assembly; 500 µm OD, 1 m length

AL300 - A 500 µm OD (300 µm core diameter) aluminum-jacketed optical fiber probe for applications that require fine spatial resolution. 300 µm alµminµm-jacketed fiber assembly; 500 µm OD, 1 m length OR125 - The OR125 is a 1/8" OD optical fiber probe used as a direct replacement for 1/8" OD O2 electrodes.

OR125 - The OR125 is a 1/8" OD optical fiber probe used as a direct replacement for 1/8" OD O2 electrodes. P1600 - The PI600 is a silicone-jacketed, polyimide-coated optical fiber probe used in environments where a non-metallic probe is required.

P1600 - The PI600 is a silicone-jacketed, polyimide-coated optical fiber probe used in environments where a non-metallic probe is required. OR125G and OR125GT - These probes are 1/8" OD optical fiber probes used as direct replacement for 1/8" OD O2 electrodes.

OR125G and OR125GT - These probes are 1/8" OD optical fiber probes used as direct replacement for 1/8" OD O2 electrodes. R Sensor Probe - 1000 µm fiber in a stainless steel 1/16" ferrule; 1.587 mm OD, 152.4 mm length

R Sensor Probe - 1000 µm fiber in a stainless steel 1/16" ferrule; 1.587 mm OD, 152.4 mm length