MP-1000 Micropipette Puller

The MP-1000 Micropipette Puller is a horizontal motorized tool designed for patch clamp and microinjection experiments, offering stability, intelligence, and humanization, making it an excellent choice.

- Overview

- Specifications

- Links

The RWD MP-1000 Micropipette Puller is a horizontally oriented motorized device, specifically engineered to address microelectrode challenges encountered in patch clamp and microinjection experiments. The MP-1000 combines stability, intelligence, and user-friendly features, effectively catering to the needs of microelectrode-related experiments while simultaneously enhancing the user experience. The RWD MP-1000 Micropipette Puller also stands out as an exceptional option for experiments involving micropipettes.

This device is outfitted with a color touchscreen and pre-programmed settings, which streamline the micropipette production process, making it more reproducible and user-friendly. Its horizontally integrated operating arm design, softening point testing capabilities, safe mode heating, and system diagnostic features work in unison to guarantee optimal pulling conditions, thus ensuring stable performance with the microelectrode puller.

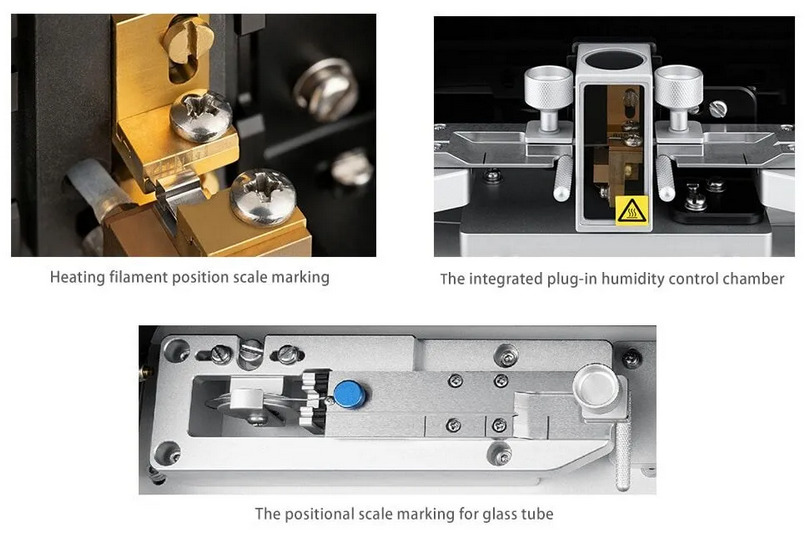

Among the other sophisticated features of the MP-1000 Micropipette Puller are the positional scale markings for the glass tube, the positional scale markings, and the fixing slot for the heating filament, all of which simplify the fixation and replacement of heating filaments. Furthermore, it includes an integrated plug-in humidity control chamber that facilitates easy plug-and-play functionality or removal.

Advantages of MP-1000 Micropipette Puller

Machine structure

A horizontally integrated manipulator arm design minimizes assembly errors, leading to an enhancement of at least 10% in the stability of electrode resistance.

Heating filament

The scale marking for positioning and the securing slot for the heating filament simplify the installation process of the heating filament.

The integrated plug-in humidity control chamber

An integrated plug-in humidity control chamber streamlines the disassembly process, decreasing the time required for replacing heating elements; it also mitigates the negative impacts of humid air on the drawing outcomes.

Button

Larger buttons with vibrant colors enhance the simplicity of operation, enabling users to press the buttons with ease.

Pull handle

An extended pull handle allows for smooth and highly efficient operation.

Built-in pull program

A three-step setup to suggest parameters, which lowers the usage threshold and minimizes the time investment needed for initial experiments.

Applications:

- Patch-clamp experiment;

- Microinjection or microelectrode: Cranial injection, Intravitreal injection, Insect injection, C. elegans injection, Embryo injection, Cell injection, Embryo Electroporation, Zebraï¬sh Embryo injection ;

- Others: 3D print nozzle, Cell capture , Microï¬uidic;

You can also visit site of the manufacturer.